Trusted company that deals in quality-made products

Showroom

Hot Die Steel made rod, flat bar, round bar and plate are produced by using cold drawn processing technology. All these products are heat treated by using quenching, annealing or tempering method to enhance their strength. Quality of these metal products has been verified as per ultrasonic test.

Spring Steel can be easily cut, shaped and heat treated to improve its yield strength. Based on its carbon content, this steel is spheroidized and heat treated. This grade of steel is used for developing washer, spring, scraper and antenna.

By shielding the landscape over the surface from harm, the provided Nitriding Steel Products range enables activities to be finished in a significantly shorter time span than different sorts of landscape repairs.

The provided Case Hardening Steel Products can be employed for greater temperature flow and are highly retardant to almost any concoction in process sewers. These products demand less excavation in introduction.

Hexagon Steel is available in rod, bar and tube forms. This class of steel is widely used in automobile, ship building and construction fields. Provided steel is also used to develop boiler heat exchanger. Quality of this steel conforms to global standard.

Aluminum bars can be processed, melted, machined and formed easily. Light in weight, this specific metal can endure heavy load. Exceptional corrosion resistance properties, low melting point and ductile nature are the key characteristics of this steel. This class of steel does not generate any odor during its processing.

Hot Rolled Steel is processed under more than 1700 degree C temperature. Bar, pipe and tube made of this steel have round shaped corner and edge. Surface scaling of this steel can easily be removed by adopting sand blasting, grinding or acid bath pickling procedures.

Nitronic Steel is preferred over commonly used stainless steel for its better rust resistance performance and higher yield strength. This version of steel is used for designing pressure vessel, boat shaft, heat exchanger and pump shaft. Quality of this steel conforms to international standard.

Industrial Steel Sheets & Plates have been developed from quality approved metals. These are used to design construction equipments like loading bucket, conveyor and bulldozer. These plates and sheets have optimum strength. Good machining attributes, high strength and precise diameter are the key factors of these metal items.

We are delivering Stainless Steel Round Bars collection that is minimally invasive as well as does not demand large introduction sites. This range has numerous other advantages as it is strong, durable and flexible in nature.

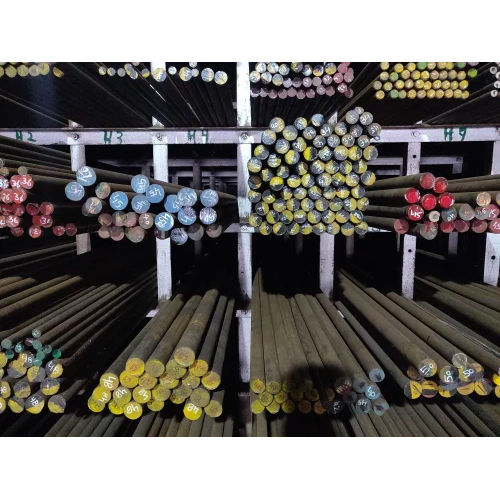

The provided EN Series Round Bars are high in caliber and like any new pipe introduction. These bars are graded to last for many decades, and these are seamless, long lasting and strong.

The provided Industrial Bright Bars support the present pipe structure and permit the undamaged segments to continue to be deployed. These bars are composed by employing hard material such as steel, metal, alloy and more.

Stainless Steel Flat Bar is known for its high tensile strength. This metal bar can be used under high temperature and corrosion prone working condition. Moreover, it possesses good welding attributes. Its application can be noticed in chemical processing field, oil and gas refineries.

Our Stainless Steel Pipes deliver effective performance in the places that require to be reinforced and repaired. As they are composed through a trenchless method, there is zero or little disruption over the surface.

Industrial Steel Flat Bar has extensive applications in machine production, construction and electromagnetic industries. Available in different surface finishes, this range of steel bar has high tensile strength irrespective of temperature level. This grade of steel is corrosion and abrasion proof.

Our collection of Industrial Steel Pipes creates a tube within a tube as well as permits the existing pipe to be employed while a new tube is introduced in it.

The advancement of our Industrial Steel Tubes range can be employed for some different kinds of pipe repairs. As it is efficient, therefore, it can spare a huge amount of cash as contrasted with conventional pipe repairs.

The offered Non Ferrous Metal Products range is an incredible choice for commercial, industrial, and residential regions, and numerous kinds of pipe repairs can be produced utilizing this innovation, sparing home and entrepreneurs both cash and time.

Provided array of Industrial Steel Products has been designed to suit precise application needs of different industries that include welding, construction, machine manufacturing and so on. These metal products have optimum strength and unique corrosion resistance attributes. Moreover, these are highly durable.

The provided Industrial Steel Round Bars range has ability to fix a broad range of diversified issues with pipes and guarantees that these bars are repaired in an opportunate manner.

Tool Steel is known for its excellent shock resistance properties and unique surface hardness. Quality of this steel conforms to global standard. Due to its chromium enriched content, this steel can withstand distortion during heat treatment process. Moreover, it can endure impact and abrasion.

Free Cutting Steel is used for high speed machining work. Application of this range of steel can be noticed in household appliance production and automobile arena. This steel is offered in bar and rod forms that are devoid of heat treated surface.

High Speed Steel is known for its excellent surface hardness, good toughness level and unique wear resistance properties. This grade of steel is mainly used for producing milling instruments, broaching tools, woodworking accessories and taps. This version of steel is cost effective.

D2 Tool Steel is often used to make blanking dies, cold forming dies, stamping dies, slitters, punches, trim dies and thread rolling dies for applications when exceptional toughness is not necessary. It has high wear and abrasion resistant properties. This steel is an air hardening, high-carbon, high-chromium tool steel.

Monel Steel is commonly used in applications with highly corrosive conditions. This steel is used for marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, shafts, fittings, fasteners, and heat exchangers. It is also used as part of metal instruments and frames of eyeglasses.

OHNS Steel is a general-purpose tool steel that is typically used in applications where alloy steels cannot provide sufficient hardness, strength and wear resistance. This grade of steel has got a wide range of application in tool and die making industries. It is well known for its high tensile strength and toughness.

Inconel Steel is used in the aerospace industry during applications where intensely high temperatures can be present, such as in jet engines. This is also highly resistant to pressure, oxidation and corrosion. Under high heat, this steel forms a protective oxide layer that makes it heat-resistant.

Duplex & Super Duplex Steel provides outstanding resistance to acids, acid chlorides, caustic solutions and other environments in the chemical/petrochemical, pulp and paper industries. This can be used in many different area like chemical processing, transport and storage, pipes for production and transportation of oil and gas, oil and gas exploration and offshore rigs.

Brass Products h are made from brass, a solid material, making it strong, hard, and formable. Brass exhibits many of the physical properties of pure copper and is also recyclable. Due to its unique properties, which include corrosion resistance, common uses for brass include applications which require low friction.

Copper Steel can enhance the chemical properties of steel by increasing its corrosion resistance. A large amount of copper can help prevent the formation of rust. This find applications in grounding, connection of ground rods to metallic structures, ground grid meshes, substations, power installations, and lightning arrestors.

Hastelloy Steel is commonly used for pipes and valves in the chemical processing and petrochemical industries. This has outstanding resistance to highly oxidizing and reducing agents, making it a great choice for moderate to severe corrosive environments. This steel is widely used in the most severe environments.

Nickel Steel is extensively used to produce stainless steel, enhancing important properties such as formability, weldability and ductility. This steel is used for heavy forgings, turbine blades, highly stressed screws, bolts, and nuts. This is also used in harsh environments such as jet engines, offshore installations and power generation facilities.

Alloy Steel is employed in producing long products used in the construction industry such as girders, structural sections, bars, rails, rods and wires. This is a type of steel alloyed with several elements such as molybdenum, manganese, nickel, chromium, vanadium, silicon, and boron. This is also used in stainless steel pipelines.

Titanium Steel is most commonly added to steel because it increases the strength and resistance to corrosion of steel. Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high temperatures without creeping. Its density is less than half that of steel, so it weighs less than pure steel and is more durable and stronger.

Carbon Steel is a metal alloy. It is a combination of two elements, iron and carbon. This is used for construction because of their strength. This has a much better tensile strength, used to make cutting tools, blades, punches, dies, springs and high-strength wire.

Mild Steel Products makes it a terrific choice of material for the construction of cages, frames, fencing and in other applications where it will not be subjected to high stress. These are made from superior quality steel that is sourced from reliable suppliers. The products that we supply are the most popularly used construction material.

Forged Steel Products act as a material resulting from alloying iron and carbon under extremely high pressure. This steel has less surface porosity, a finer grain structure, more tensile and fatigue strength, and greater ductility than any other processed steel. They are known for its corrosion resistance finish and precise dimension.

Phosphor Bronze Steel is used to make parts for many industrial fields. It's an alloy of copper containing both tin and phosphorus. This gives the metal more fluidity in its molten state, allowing for easier casting. This is primarily used for electrical products because they have superb spring qualities, high fatigue resistance, excellent formability, and high corrosion resistance.

Shaft & Shaft Products are manufactured, designed and supplied by using premium quality of raw materials by our experts. These shafts are easily available as precision shafts and ultra-precision shafts. They are available as well as cut to length sizes.

We accept retail orders only below 400 Kg.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese